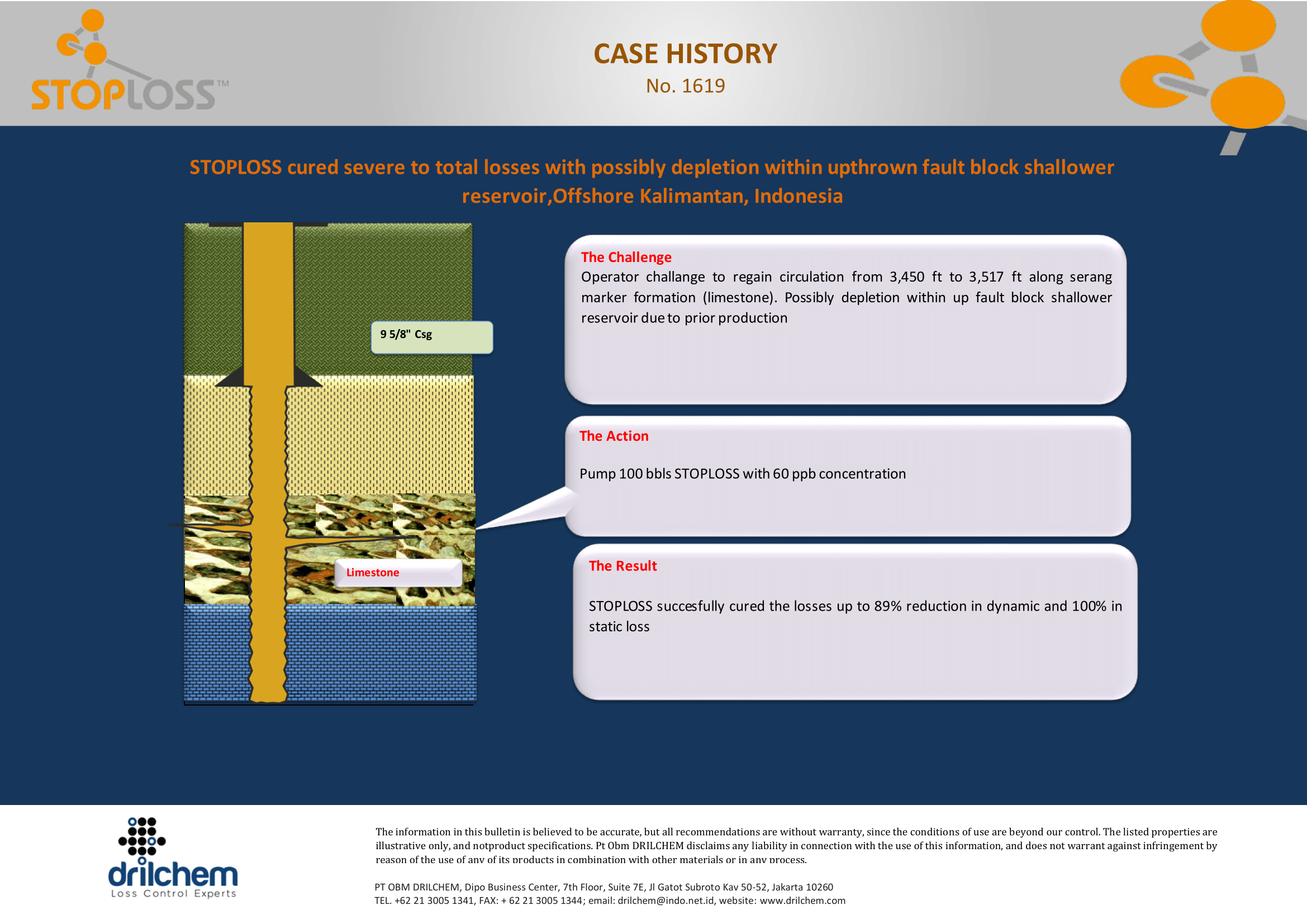

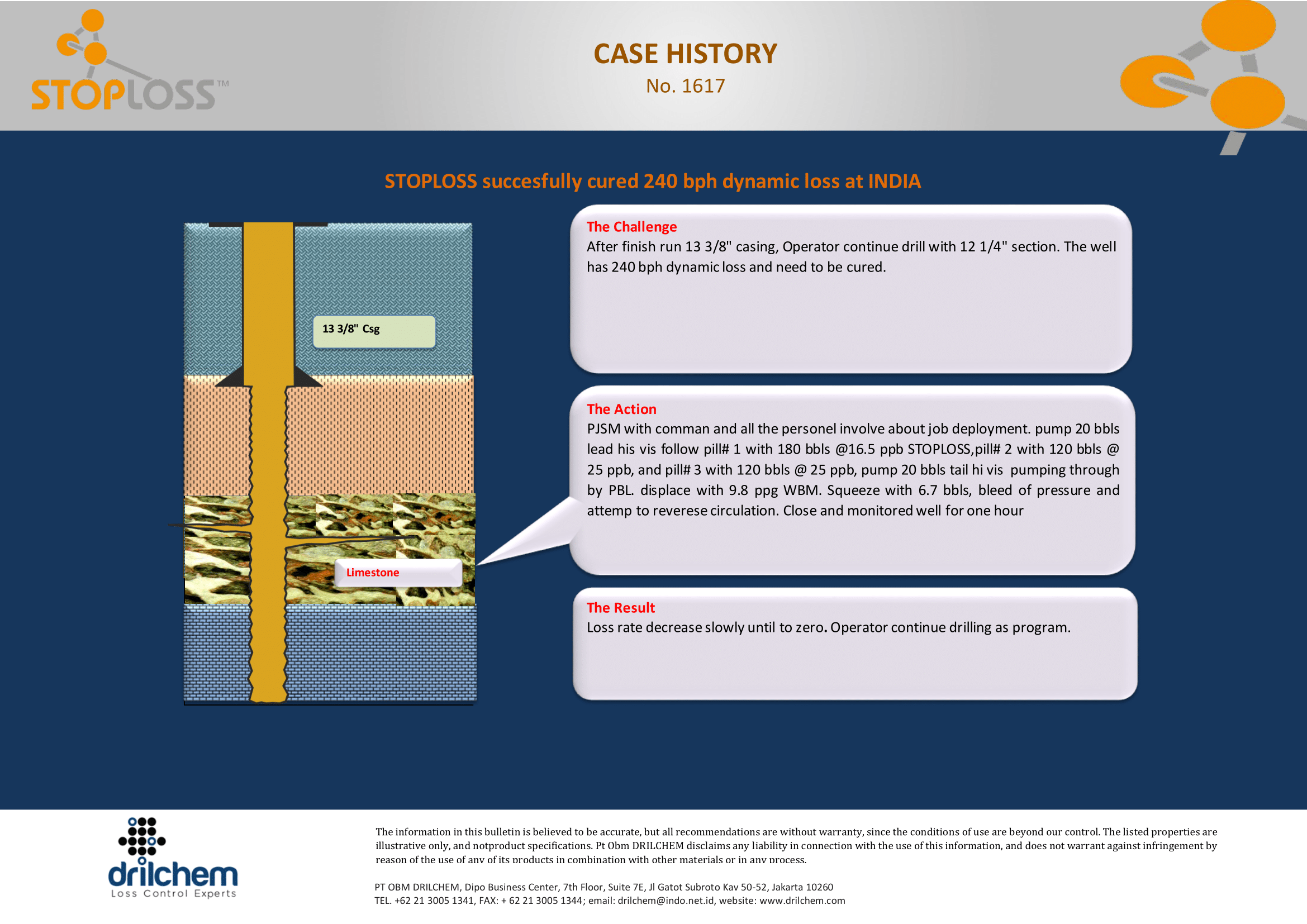

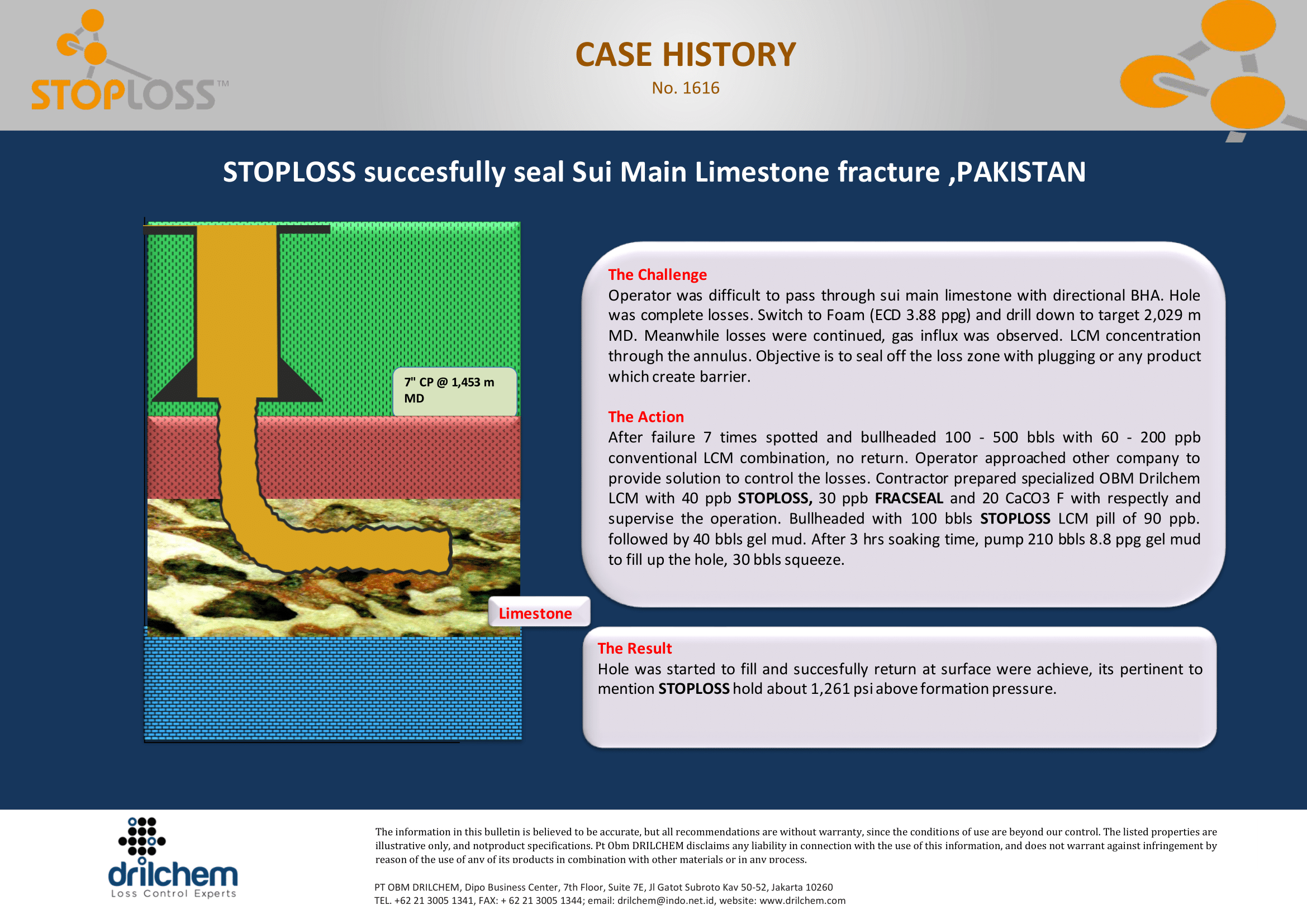

The Challenge:

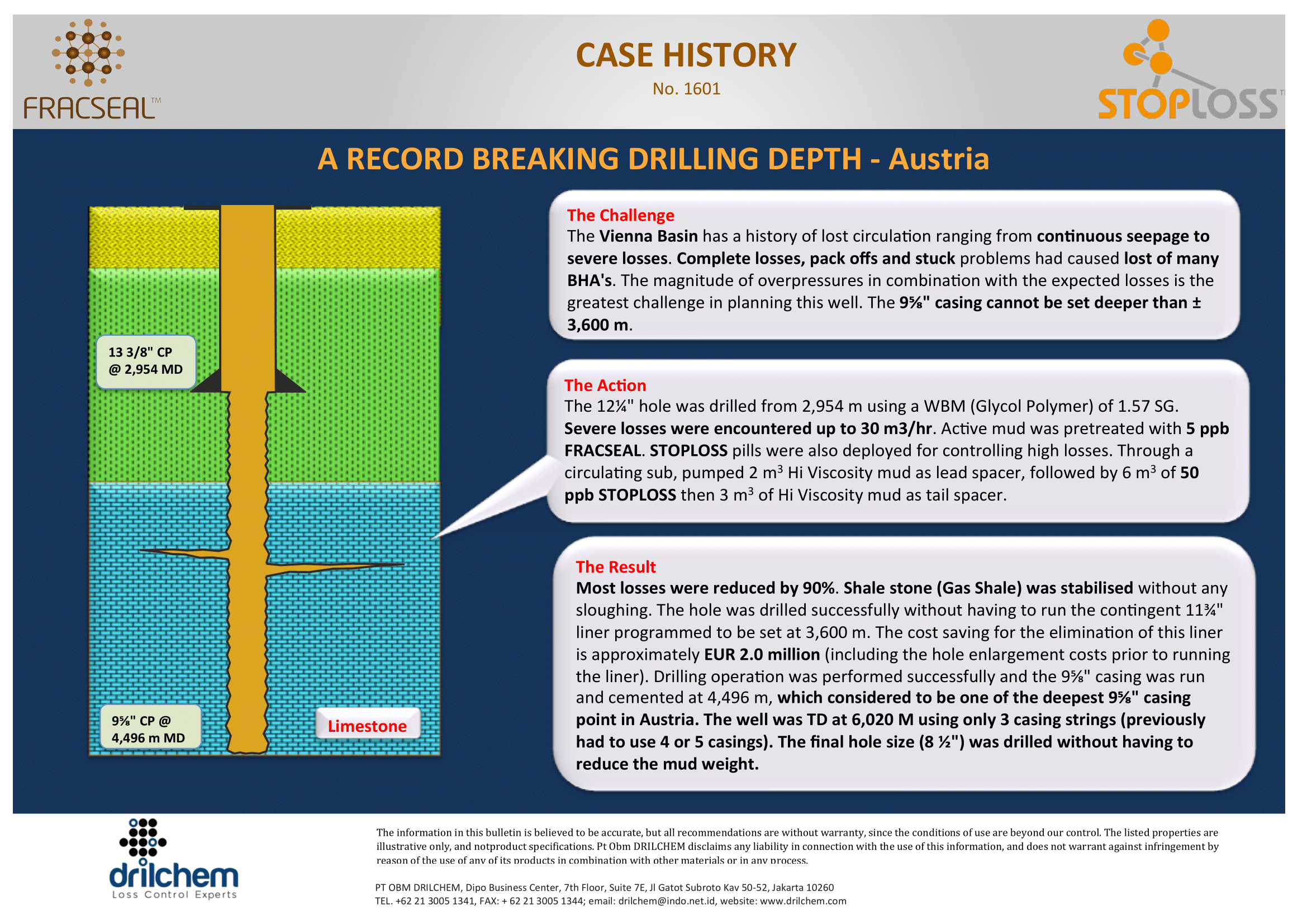

The Vienna Basin has a history of lost circulation ranging from continuous seepage to severe losses. Complete losses, pack offs and stuck problems had caused lost of many BHA’s. The magnitude of overpressures in combination with the expected losses is the greatest challenge in planning this well. The 9⅝” casing cannot be set deeper than ± 3,600 m.

The Action:

The 12¼” hole was drilled from 2,954 m using a WBM (Glycol Polymer) of 1.57 SG. Severe losses were encountered up to 30 m3/hr. Active mud was pretreated with 5 ppb FRACSEAL. STOPLOSS pills were also deployed for controlling high losses. Through a circulating sub, pumped 2 m³ Hi Viscosity mud as lead spacer, followed by 6 m³ of 50 ppb STOPLOSS then 3 m³ of Hi Viscosity mud as tail spacer.

The Result:

Most losses were reduced by 90%. Shale stone (Gas Shale) was stabilised without any sloughing. The hole was drilled successfully without having to run the contingent 11¾” liner programmed to be set at 3,600 m. The cost saving for the elimination of this liner is approximately EUR 2.0 million (including the hole enlargement costs prior to running the liner). Drilling operation was performed successfully and the 9⅝” casing was run and cemented at 4,496 m, which considered to be one of the deepest 9⅝” casing point in Austria. The well was TD at 6,020 M using only 3 casing strings (previously had to use 4 or 5 casings). The final hole size (8 ½”) was drilled without having to reduce the mud weight.