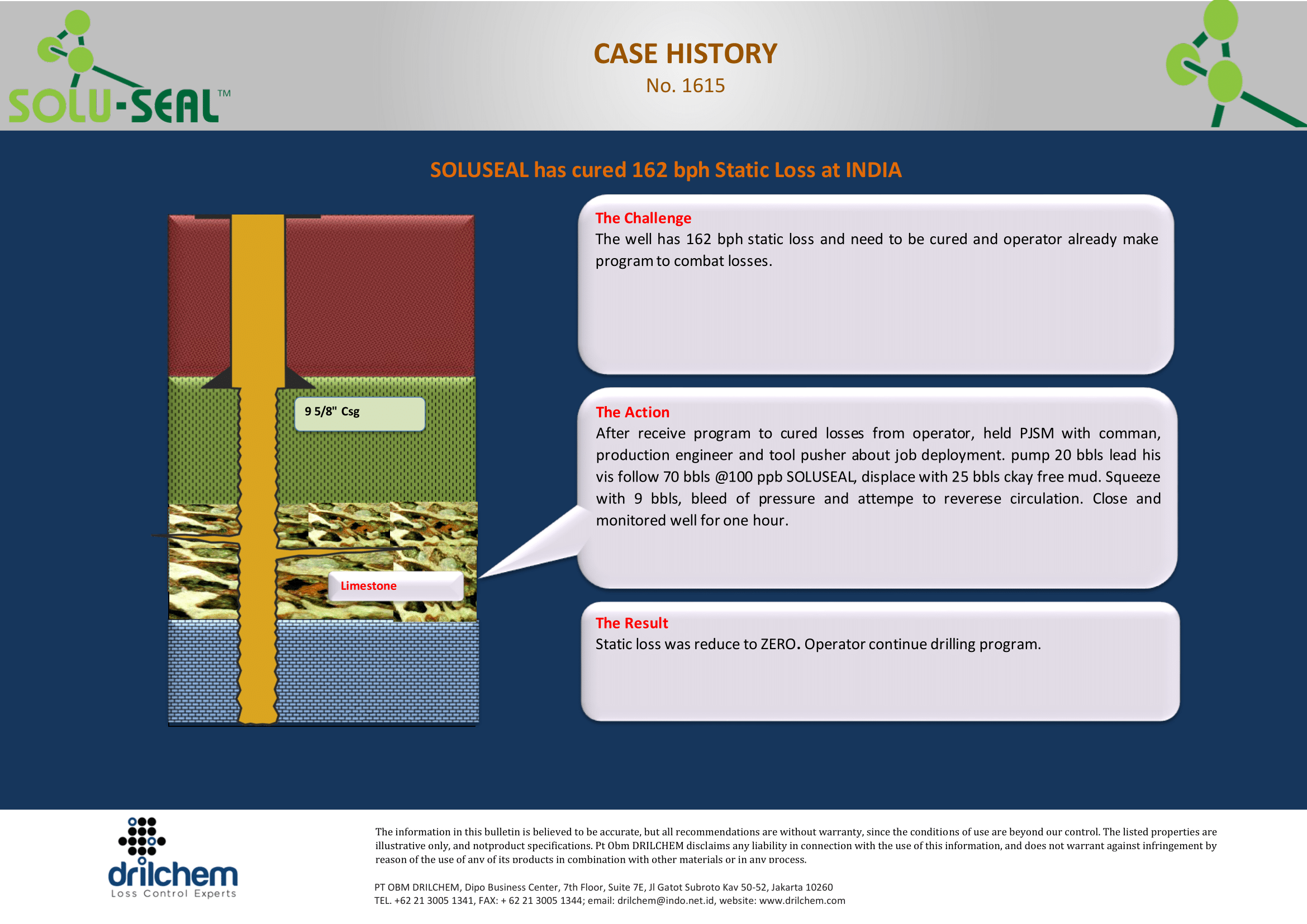

The Challenge:

The well has 162 bph static loss and need to be cured and operator already make program to combat losses.

The Action:

After receive program to cured losses from operator, held PJSM with comman, production engineer and tool pusher about job deployment. pump 20 bbls lead his vis follow 70 bbls @100 ppb SOLUSEAL, displace with 25 bbls ckay free mud. Squeeze with 9 bbls, bleed of pressure and attempe to reverese circulation. Close and monitored well for one hour.

The Result:

Static loss was reduce to ZERO. Operator continue drilling as program.