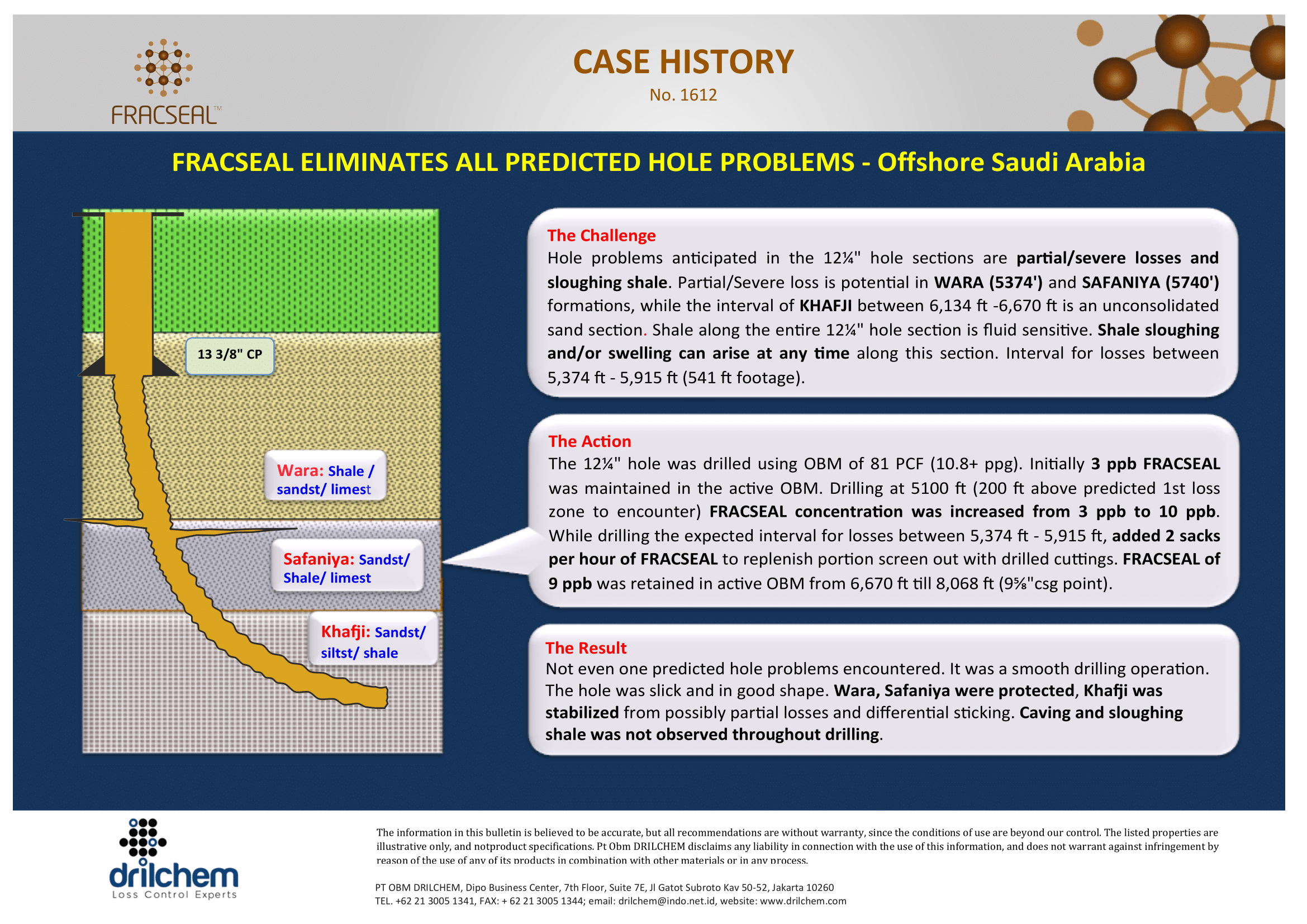

The Challenge:

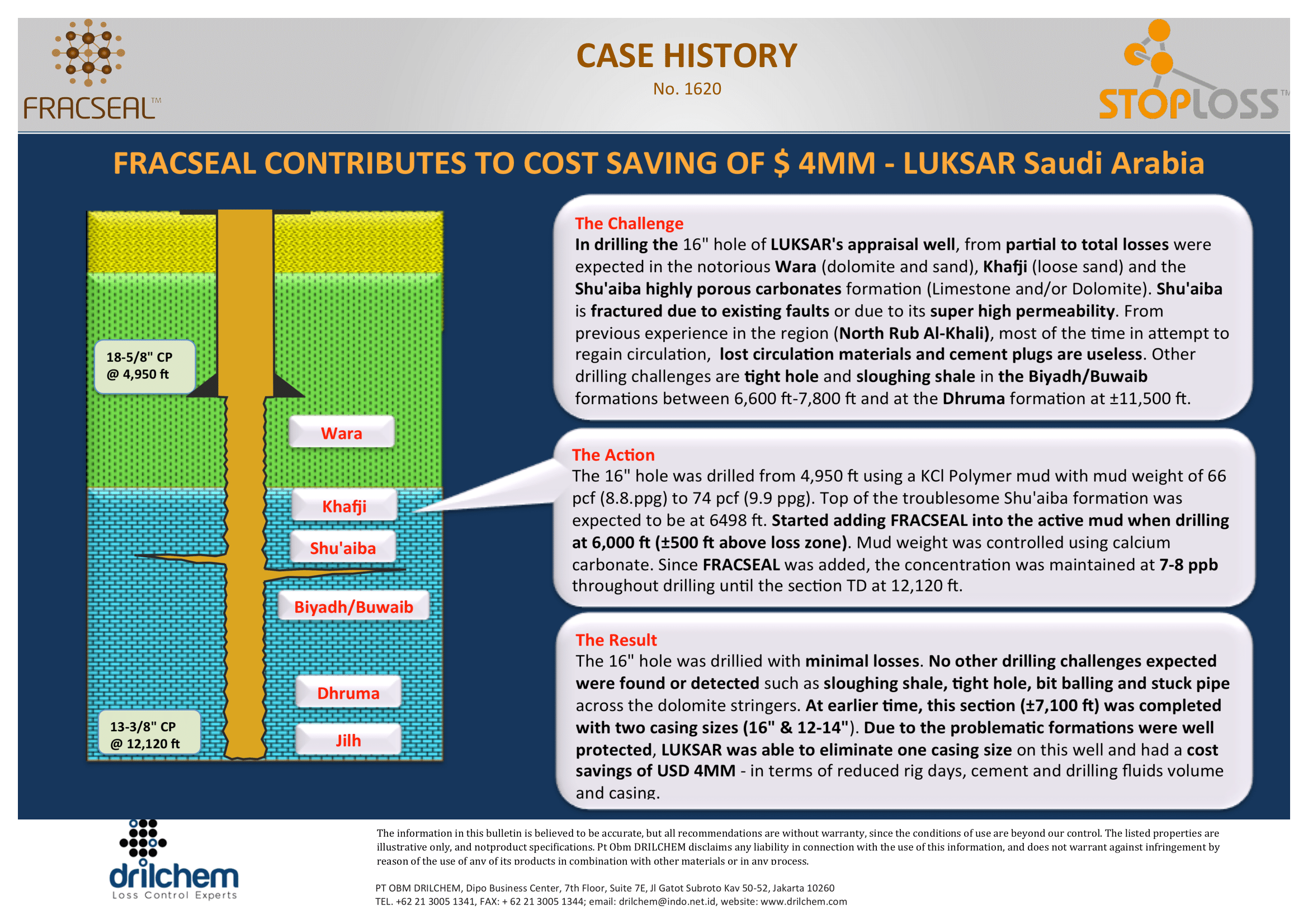

In drilling the 16″ hole of LUKSAR’s appraisal well, frompartial to total losses were expected in the notorious Wara (dolomite and sand), Khafji(loose sand) and the Shu’aiba highly porous carbonatesformation (Limestone and/or Dolomite). Shu’aiba isfractured due to existing faults or due to its super high permeability. From previous experience in the region (North Rub Al-Khali),most of the time in attempt to regain circulation, lost circulation materials and cement plugs are useless.Other drilling challenges are tight hole and sloughing shale in the Biyadh/Buwaib formations between 6,600 ft7,800 ft and at the Dhruma formation at ±11,500 ft.

The Action :

The 16″ hole was drilled from 4,950 ft using a KCI Polymer mud with mud weight of 66 pcf (8.8.ppg) to 74 pcf (9.9 ppg). Top of the troublesome Shu’aiba formation was expected to be at 6498 ft. Started adding FRACSEAL into the active mud when drilling at 6,000 ft (±500 ft above losszone). Mud weight was controlled using calcium carbonate. Since FRACSEAL was added, the concentration was maintained at 7-8 ppb throughout drilling until the section TD at 12,120 ft.

The Result :

The 16″ hole was drillied with minimal losses. No other drilling challenges expected were found or detected such as sloughing shale, tight hole, bit balling and stuck pipe across the dolomite stringers. At earlier time, thissection (±7,100 ft) was completed with two casing sizes (16″ & 12- 14″). Due to the problematic formations were well protected, LUKSARwas able to eliminate one casing size on this well and had a cost savings of USD4MM – in terms of reduced rig days, cement and drilling fluids volume and casing.